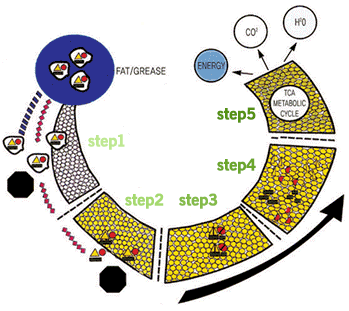

Step 1 : Dispense fat & oil

Step 2 : Each dispersed molecule is

cleaved to form fatty acids & triglycerides

Step 3 : Separation into fatty acids andtriglycerides

Step 4 : The hydrogen and carbonmolecules in the separated fatty acids

and triglycerides are broken

Step 5 : Conversion to carbon dioxide andwater through TCA metabolism pathway

All Food waste is made of Glucose molecules. We supply a specially made mixture of Microbes & Enzymes, which work like in citric acid cycle(Krebs Cycle), to disperse the FOG (Fat, Oil & Grease) of the food waste and convert them to Carbo Hydrates and then convert Carbo-hydrates into Heat, Carbon Dioxide & water

.jpg)

.jpg)

Food waste is completely decomposed by BioRen,aunique Star type Filter Media developed by our team,and micro organisms, and turned into water and carbondioxide, and then it goes down to sewer